Campion Sail and Design

Light-weight, simplified canoe yawl: 15 ft by 5 ft 3 - B15 - is the origin of the Imp.

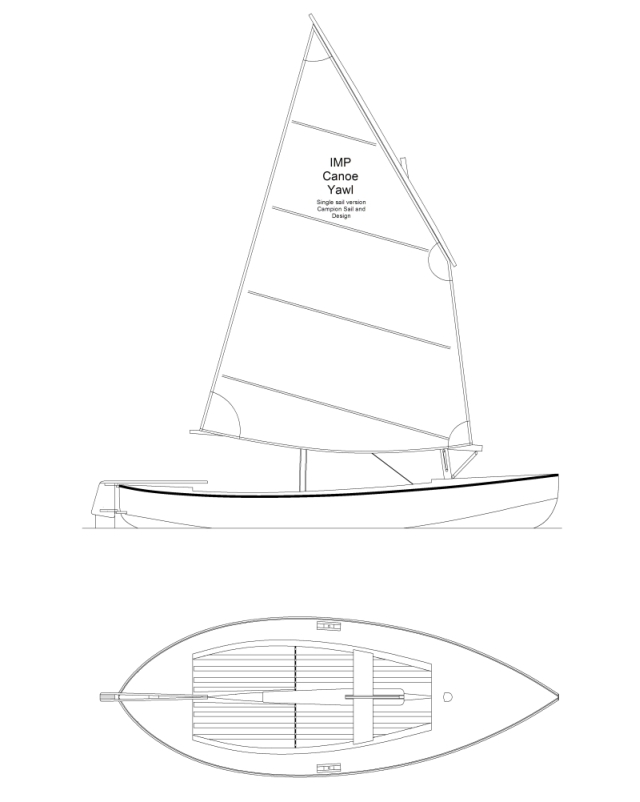

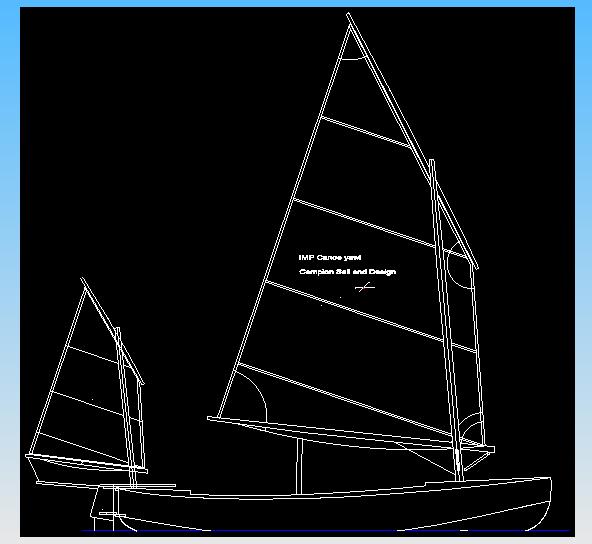

Below is the modified version of the 15, the IMP: the same apart from the topsides at the stern, which have been eased to aid construction, with a single balanced lug for simplicity - as were some of the original 19th century canoe yawls, including at least one by Albert Strange. For the record, canoe yawls are not and never have been narrow-beamed sailing or paddling canoes that have a so-called 'yawl rig' even though they developed out of the often ketch rigged sailing canoes of the last quarter of the 19th century. 'Canoe' refers to the double-ended hull shape - intended from the very beginning to be rowed, not paddled, when not under sail as a result of the wide beam - as well as being a reminder of its origins, whilst 'yawl' meant a small boat - which may or may not be 'yawl rigged'. The rig of a canoe yawl with an additional sail aft of the main is more accurately described as one of 'main and mizzen'. Both options - main and mizzen and una rig - have been drawn up for the IMP.

Plans include seven A1 sheets of drawings plus keyed construction and sail plan notes.

Loa: 4.510m - Beam over gunwales: 1.650m - Overall depth, bow to keel: approx 725mm - Freeoboard at approx 0.300t: Bow: 560mm - Lowest point of sheer: 330mm- Stern: 450mm - Sail area is about 7 sq m for the main, 1.4 for the mizzen if used - Displacement: at wl 125mm is 0.200t - at wl 140mm 0.250t - at wl 157mm 0.300t.

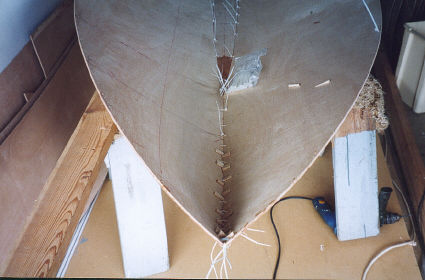

The bottom sections are fully conically developed, which ensures that the fore body and after body are very strong, exceptionally rigid and very light. Note the amount of curvature in the first two bulkheads above. There is no torturing of the ply whatsoever, and the panels bend naturally to shape. Once the bottom is joined together, each side can be sewn on in 20 minutes - apart from the last 18 to 24" of the stern - see left and immediately below - where, because of the very full stern in plan view, very flat buttocks in profile and flared topsides, it might well take an hour to ensure that each panel is absolutely perfectly aligned. This type of stern has considerable reserve buoyancy, unlike the slim conventional canoe sterns, as well as being attractive, so perhaps the extra work can be excused, but is less suitable for the inexperienced builder. Note, too, how well the panels fit together. In the photo on the left can be seen the small plywood tabs that maintain perfect alignment at the keel, and which are removed later

Quite a pretty shape for a simple hard-chined dinghy - a truly curvacious little craft for two panels a side construction